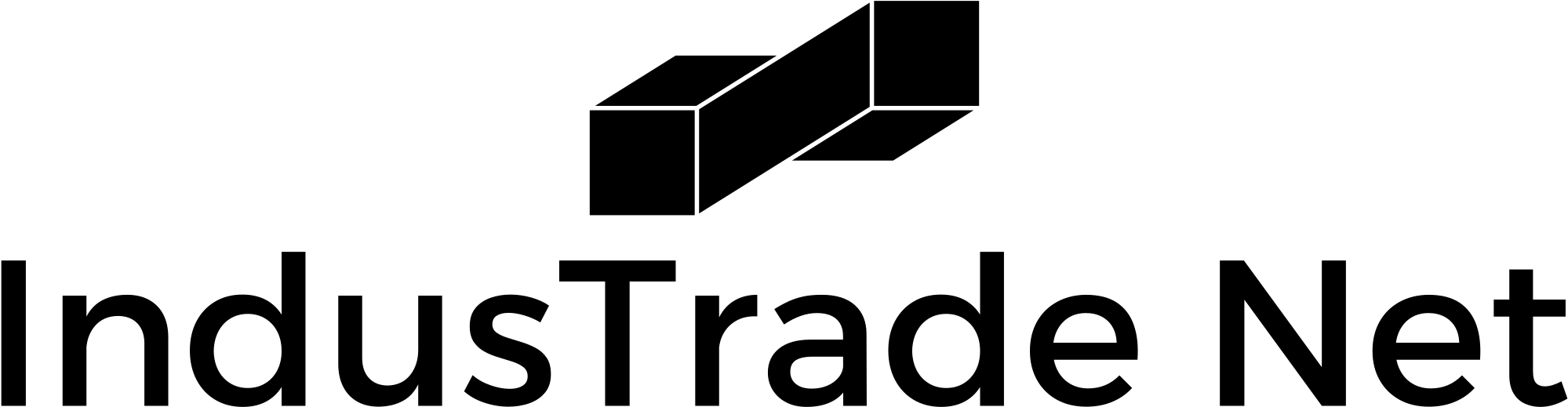

Description

Features of composite printer metal mold for sale

– Made of high-quality metal alloy for durability and strength.

– Precision engineering and design for accurate and consistent printing results.

– Compatible with a wide range of 3D printers and printing materials.

– Easy to install and use, with user-friendly instructions and support.

– Ideal for creating complex and intricate shapes and designs with high precision and detail.

– Saves time and money by reducing the need for manual labor and post-processing.

– Provides a cost-effective and efficient solution for small to medium-scale production runs.

– Enhances the overall quality and performance of 3D printing processes.

– A must-have tool for professionals and hobbyists alike who demand the best in 3D printing technology.

– Invest in the Features of Composite Printer Metal Mold for superior results and long-lasting value.

Material composition of composite printer metal mold:

– The material composition of composite printer metal mold is a crucial aspect of its performance and durability.

– Composite printer metal molds are widely used in various industries, including automotive, aerospace, and medical, due to their ability to produce complex and precise parts.

– The composition of the mold determines its mechanical properties, such as strength, stiffness, and toughness, as well as its resistance to wear, corrosion, and thermal deformation.

– The most common materials used in composite printer metal molds are metals, such as aluminum, steel, and titanium, and polymers, such as epoxy and polyurethane.

– The choice of material depends on the specific application requirements, such as the part geometry, production volume, and environmental conditions.

– The composition of the mold can also affect the manufacturing process, such as the mold's ability to withstand high temperatures and pressures during injection molding or casting.

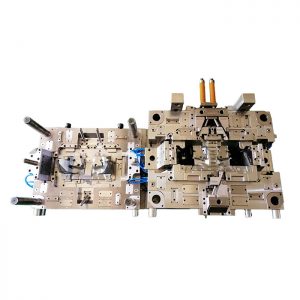

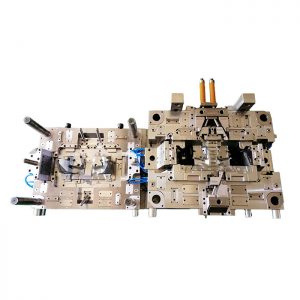

Design features of composite printer metal mold:

-Composite material: The printer metal mold is made of composite material, which makes it lightweight and durable.

-Precision design: The mold is designed with precision to ensure that it produces high-quality prints every time.

-Easy to use: The mold is easy to use, with a simple and intuitive design that makes it accessible to users of all skill levels.

-Customizable: The mold is customizable, allowing users to adjust its settings to suit their specific needs and preferences.

-Versatile: The mold is versatile, capable of producing a wide range of prints and designs.

-Efficient: The mold is designed to be efficient, with a streamlined workflow that minimizes waste and maximizes productivity.

-Cost-effective: The mold is cost-effective, with a low cost of ownership and minimal maintenance requirements.

Compatibility of composite printer metal mold:

– Composite printer metal molds are made from a combination of materials, such as metal and plastic, to create a durable and versatile mold.

– Compatibility between the composite printer metal mold and the 3D printer is crucial to ensure that the mold can be used effectively and efficiently.

– Factors such as the size and shape of the mold, the type of printer used, and the printing materials used can all affect compatibility.

– It is important to choose a composite printer metal mold that is compatible with the specific 3D printer being used to ensure optimal performance and results.

– Regular maintenance and cleaning of the mold and printer can also help to maintain compatibility and extend the lifespan of both components.

Cost-effectiveness of composite printer metal mold:

– The composite printer metal mold is a new product that promises to revolutionize the manufacturing industry by providing a cost-effective solution for creating high-quality metal molds.

– This product is designed to be used with 3D printers, allowing manufacturers to create complex metal molds quickly and easily, without the need for expensive and time-consuming traditional manufacturing methods.

– The cost-effectiveness of this product is due to its unique composite material, which is made from a combination of metal and plastic. This material is not only cheaper than traditional metal molds, but it is also more durable and resistant to wear and tear.

– The composite printer metal mold is also highly customizable, allowing manufacturers to create molds that are tailored to their specific needs and requirements. This means that they can produce high-quality products at a fraction of the cost of traditional manufacturing methods.

-the cost-effectiveness of the composite printer metal mold makes it an attractive option for manufacturers looking to reduce their production costs while maintaining high-quality standards.

Xuzhong is a professional composite printer metal mold supplier. If you want to buy this product, please come to us for consultation. We will provide you with considerate services and high-quality products.

Related news of Composite Printer Metal Mold

Advantages of customized composite printer metal molds

Application of cost-effective composite printer metal mold

Maintenance and repair of composite printer metal mold

Extremely high-precision composite printer metal mold provided

How to operate the composite printer mold exporter during use

Manufacturing process of composite printer metal mold

Features of customized composite printer mold: Enhancing efficiency

Reviews

There are no reviews yet.